In November’s news, we talked about some of the history of The Factory, the building in which BCC is housed. Our aim has been to get a diverse range of businesses and individuals working here in order to foster an environment of innovation and creativity. This month we take a look at two new tenants of our amazing space.

Sharyn Hight - Lattitude Global Volunteering

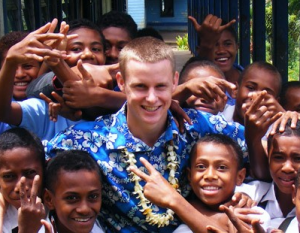

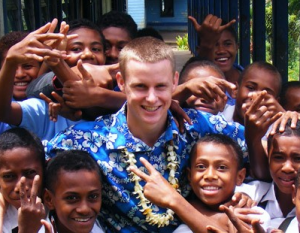

Sharyn is a friendly, passionate person who manages Lattitude Global Volunteering, a UK based firm which has been around for over eight years. Sharyn oversees four staff who manage 240 volunteers. The company grew out of a much older organisation which was more focused on traditional gap year experiences for students finishing school. The focus of Lattitude has now shifted towards volunteering and today they send volunteers to twelve different countries around the world from Fiji to Malawi to Canada.

Sharyn and the Latitude staff moved into The Factory two months ago and have been very happy since. “Its really cool, there are a lot of neat people around and the atmosphere is great,” says Sharyn. “There are accountants and graphic designers working in the same space as us and we talk to them and kind of take in new ideas by osmosis. It’s also great to talk to people about our volunteers coming back from overseas to help them find jobs and get them involved in things going on here in New Zealand.”

The company usually has about 160 volunteers overseas at a time and around 80 foreign volunteers in New Zealand whose average placement time is six months. “We try to place them so that they can develop their skills and be comfortable with what they are doing”, says Sharyn. “This could mean anything from helping teach PE or arts in the UK to working in an orphanage in Vietnam, depending on the student’s level of comfort being in a foreign country and their experience. What we are focusing on now is consolidating what we do well, and trying to build up our networks of returning volunteers.”

Mike Long – Altus

Mike has been working in The Factory since November in a small office connected to a larger workroom. Everything in his work space is covered with electronic equipment from wires and chips to a large UAVs hanging off one wall. Altus builds custom UAVs (unmanned aerial vehicles)- “not drones,” says Mike, “not so much me, but some of the guys in Altus get upset when you call them drones because that makes people think of the ones that blow things up.” What Altus really does is solve problems with remotely controlled devices, which usually, but not always means UAVs. In one case the Altus team were hired to go to a dam that had the water drained out of it so they could lower a wirelessly controlled camera into large pipes and check for cracks.

Altus UAVs are top of the line, a big step away from the type of drones you might fly for fun, and are custom built for each client. They are usually made for survey work but Altus also branches into areas such as filming; in fact, the team has recently been hired by CNN. “The market is challenging because there’s always new UAVs and new technology coming out so we need to stay ahead of the competition,” says Mike. Altus focuses on doing what they do really well and having the safest UAVs out there. “I used to be an avionics technician in the air force and about half of us come from some kind of military background. We build our UAV’s with the type of precision and care that goes making manned aircraft.”

Of the six people on the team, Mike is the only one in Palmerston North. “I used to work at home but then I couldn’t really switch off after work because I would see bits and pieces sitting around and think – oh I need to get onto that. My wife was also starting to get a bit annoyed. So I looked around at work spaces in Palmy but they were all big cold empty spaces with no windows. I was familiar with BCC because I had taken part in Innovate and someone told me there was an office space open here if I wanted – and it couldn’t have worked out better. Electricity, heating, Wi-Fi, and coffee plus a nice space with windows to look out of. I order a lot of packages and I can trust that they are kept safe even if I’m not here, and of course Mel (The Factory manager) is just awesome.”

What a busy year 2015 was and we expect 2016 to be the same. Our highlights included over 100 emerging entrepreneurs starting their journey with Innovate, local team Generation Zedd being recognised in the Young Enterprise Scheme and over 200 participating in Startup Weekend style events in the Manawatu. Calfsmart and Biolumic completed significant capital raises and Sprout Agritech Accelerator was launched with the first cohort featuring eight companies from around NZ. With the launch of The Factory, our co-working, coffee lounge space, there has never been a better time to start a technology company. Rest assured that in 2016 BCC will again focus on playing its role in contributing to the growing entrepreneurial sectors in Manawatu and New Zealand.

What a busy year 2015 was and we expect 2016 to be the same. Our highlights included over 100 emerging entrepreneurs starting their journey with Innovate, local team Generation Zedd being recognised in the Young Enterprise Scheme and over 200 participating in Startup Weekend style events in the Manawatu. Calfsmart and Biolumic completed significant capital raises and Sprout Agritech Accelerator was launched with the first cohort featuring eight companies from around NZ. With the launch of The Factory, our co-working, coffee lounge space, there has never been a better time to start a technology company. Rest assured that in 2016 BCC will again focus on playing its role in contributing to the growing entrepreneurial sectors in Manawatu and New Zealand.